Digital Twin for Treatment Plants

A digital twin for plant O&M—driving energy and chemical savings, recommending optimal settings, enabling predictive maintenance, reducing compliance risk, and supporting troubleshooting, training, and collaboration in dynamic conditions.

The Challenge

Operators are overburdened. Systems are complex. Opportunities go unseen.

Many treatment plants rely on complex processes and institutional knowledge that often disappears with staff retirements. With tightening regulations and rising O&M costs, utilities need more than SCADA—they need a real-time digital twin that guides every operator to make smarter, faster decisions.

$180B

Per year required to maintain U.S. water wastewater operations.

50%

Of total operating costs are tied to pumping, energy, chemicals and sludge management.

30B

Kilowatt-hours consumed annually by U.S. treatment plants, costing $2.7 billion.

5x

Wastewater contains five times more energy than what is needed to treat it.

Challenges your peers have addressed with APOLLO™:

- High energy and chemical costs

- Loss of operator knowledge

- Unexpected equipment failures

- Slow, inconsistent troubleshooting

- Compliance tracking issues

- Manual process inefficiencies

The Opportunity

Rapid ROI and capital flexibility.

With APOLLO™, utilities gain a true operations copilot—one that learns, adapts, and advises. From real-time savings to long-term planning, APOLLO™ helps teams manage by exception, avoid trial-and-error tuning, and drive systemic efficiency without compromising compliance.

Rapid ROI

18 to 24 months payback. In addition, every $1 saved creates $8 to $10 in capital flexibility.

Data integrations

Works with your existing SCADA and LIMS/WIMS.

Smart digital advisors

APOLLO has built-in advisors that provide optimal guidance for each stage of treatment.

Knowledge capture

Retains SOPs, operator insight, and historical context to future-proof your team.

Having real-time analytics beyond what SCADA gives us is a game changer for senior management and operations staff.

Get started with APOLLO™

Discover how Aquasight’s APOLLO™ gives operators and engineers real-time insights and intelligent guidance to improve treatment performance, reduce energy and chemical use, and stay in compliance—all without adding hardware or waiting years to deploy.

Solution Overview

APOLLO™ helps you operate smarter, adapt faster, and make the most of every drop, dollar, and decision.

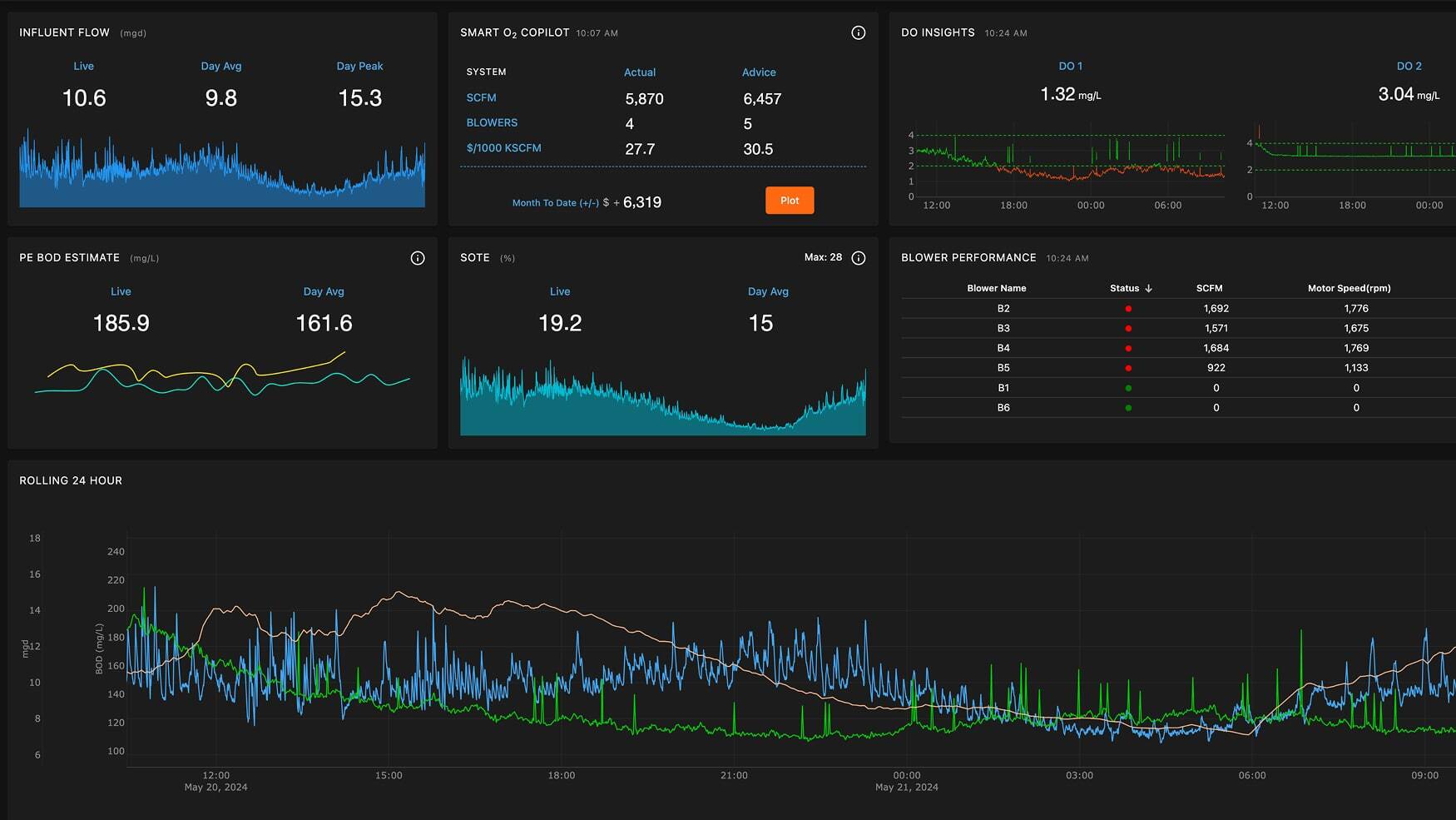

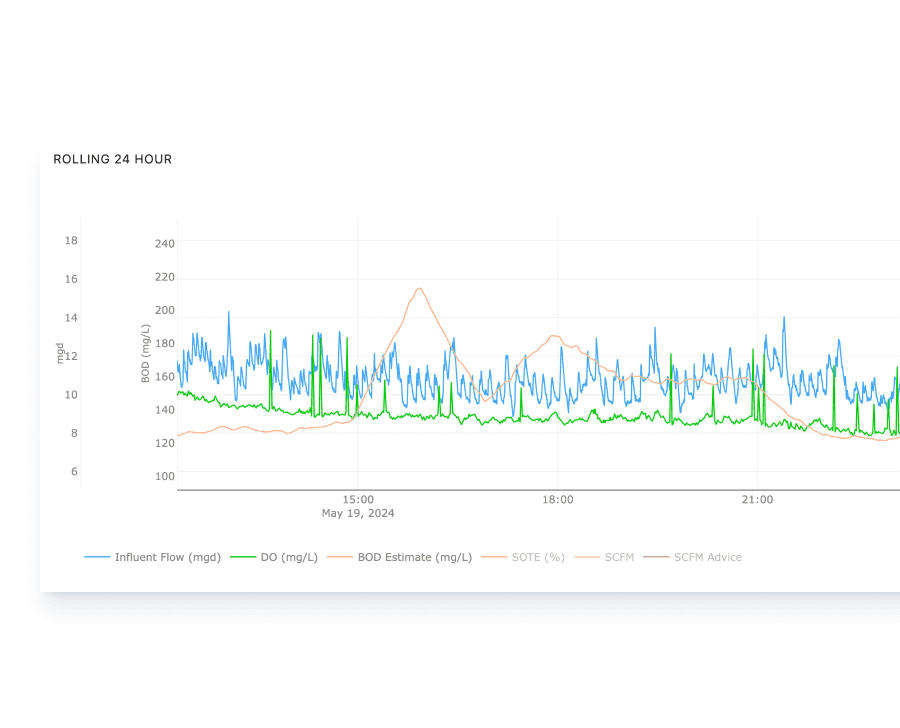

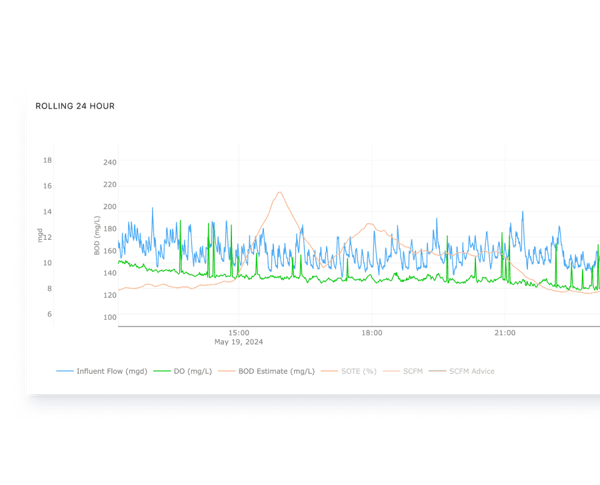

Real-time process intelligence

From influent to treatment to effluent, APOLLO™ continuously monitors treatment performance and gives direct feedback on process improvements.

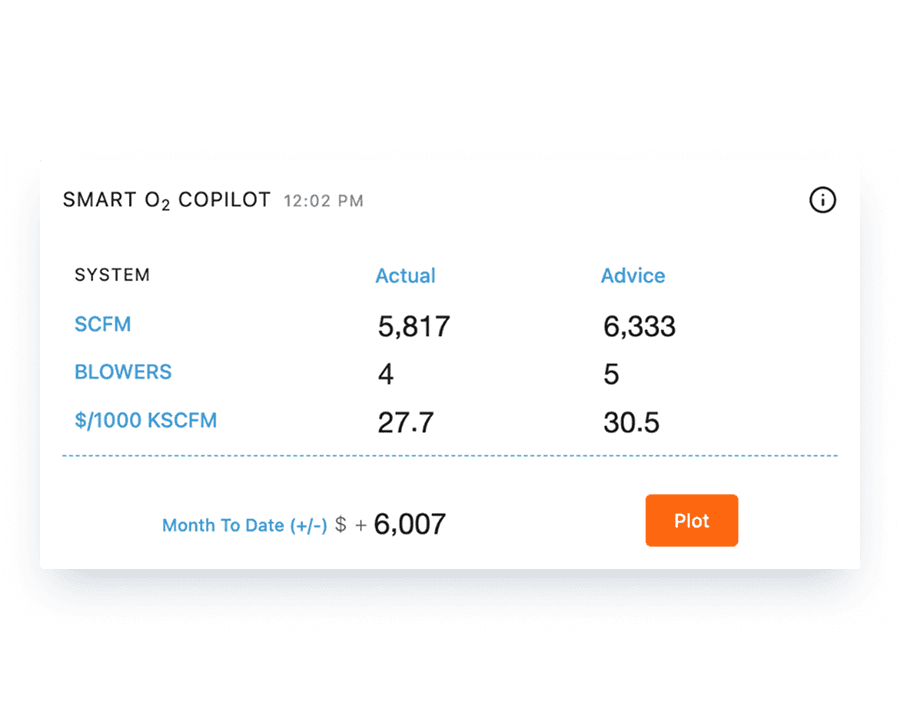

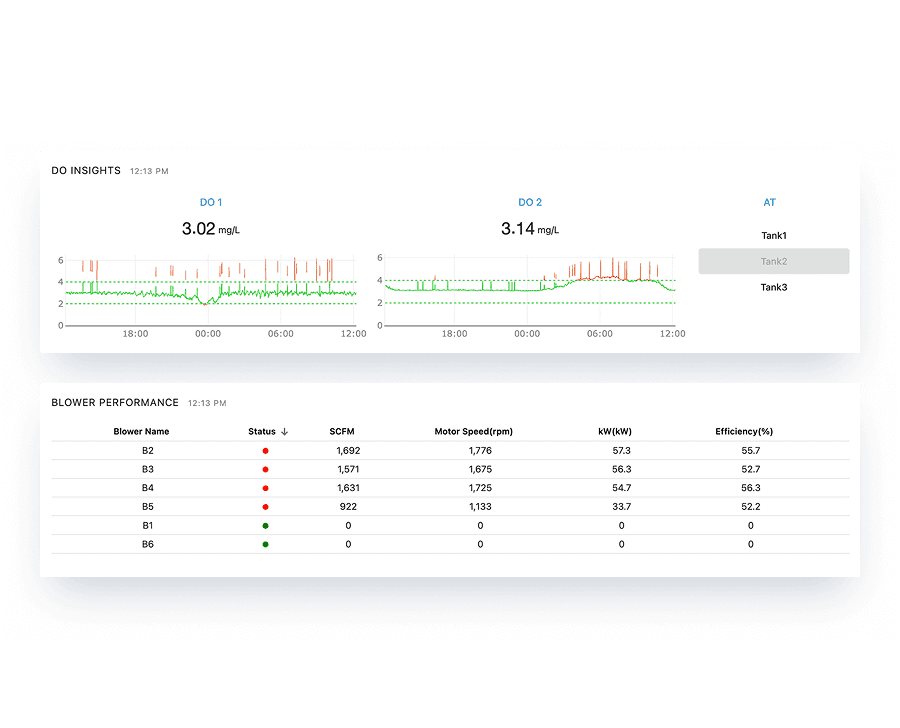

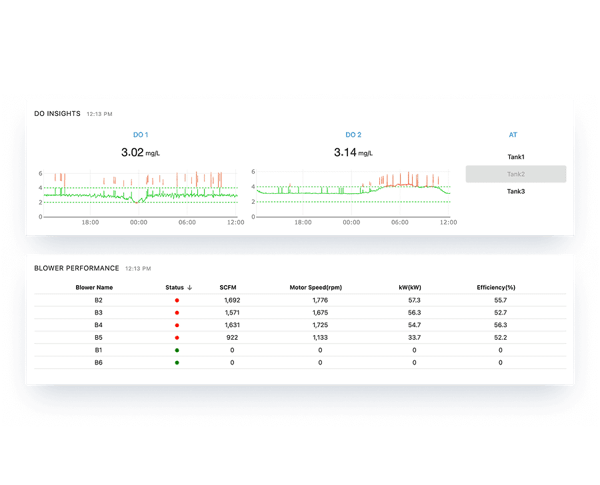

Optimization & predictive maintenance

Built-in advisors recommend the most cost-effective operations while ensuring compliance across all unit processes. AURA™ also monitors your most critical equipment and flags anomalies before they become issues.

Digital operations assistant

Train your workforce, retain knowledge of your most experienced personnel, and support decision-making with data-backed insights—available from control room or tablet.

Features

Everything your treatment operators, managers, and execs need, all in one platform.

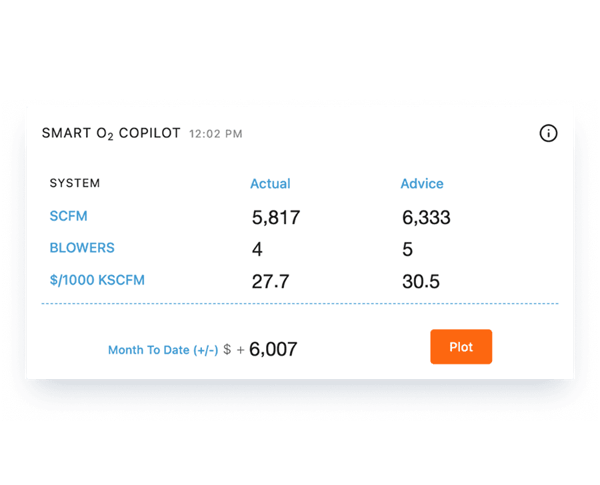

Blower & aeration optimization

Polymer dosing & dewatering insights

Influent water quantity and quality forecasting

Drinking water chemical treatment optimization

Smart advisors "copilot" & knowledge capture

Effluent monitoring & permit tracking

Centrifuge & solids optimization module

SAMI: Autonomous monitoring & alerts

Integrates with historian, lab systems, and weather stations

24/7 access on desktop or tablet

Smarter treatment operations, proven in the field

Aquasight’s APOLLO™ isn’t just software—it’s a trusted performance partner used by some of the largest utilities in the U.S. From Central San to Louisville to Haverhill, APOLLO™ is delivering real-time intelligence that improves energy and chemical efficiency, simplifies operations, and strengthens compliance across treatment facilities of all sizes.

Who we help

APOLLO™ supports everyone in your plant—not just the SCADA screen.

Directors

APOLLO™ helps directors make confident, data-informed decisions that align with permit goals, budget constraints, and treatment targets. It transforms raw data into actionable insights—ensuring directors have a pulse on every key metric without the noise.

Engineers

APOLLO™ equips engineers with powerful tools to evaluate treatment unit efficiencies, calibrate control strategies, and test the impact of operational changes before implementation. With predictive modeling and process simulations, engineers can drive innovation and improve resiliency.

Utility Operators

APOLLO™ acts as a digital co-pilot, providing operators with continuous feedback on process conditions and intelligent guidance for adjustments. Whether it's DO levels, chemical dosing, or blower settings, APOLLO™ ensures optimal results with minimal guesswork.

Maintenance Technicians

APOLLO™’s predictive maintenance insights highlight emerging equipment issues before they cause disruptions. Technicians can focus resources on high-risk assets and schedule interventions proactively, enhancing reliability and reducing costly emergencies.

Asset Managers & Finance

With APOLLO™, asset and finance leaders can understand how treatment performance connects to lifecycle costs, deferred maintenance, and capital allocation. The result? Smarter investments and defensible funding strategies.

Compliance Officers & Environmental Managers

APOLLO™ provides early warnings on permit limit trends, tracks nutrient removal effectiveness, and generates defensible reports. It gives compliance officers peace of mind and enables a proactive, not reactive, approach to environmental stewardship.

Directors

APOLLO™ helps directors make confident, data-informed decisions that align with permit goals, budget constraints, and treatment targets. It transforms raw data into actionable insights—ensuring directors have a pulse on every key metric without the noise.

Engineers

APOLLO™ equips engineers with powerful tools to evaluate treatment unit efficiencies, calibrate control strategies, and test the impact of operational changes before implementation. With predictive modeling and process simulations, engineers can drive innovation and improve resiliency.

Utility Operators

APOLLO™ acts as a digital co-pilot, providing operators with continuous feedback on process conditions and intelligent guidance for adjustments. Whether it's DO levels, chemical dosing, or blower settings, APOLLO™ ensures optimal results with minimal guesswork.

Maintenance Technicians

APOLLO™’s predictive maintenance insights highlight emerging equipment issues before they cause disruptions. Technicians can focus resources on high-risk assets and schedule interventions proactively, enhancing reliability and reducing costly emergencies.

Asset Managers & Finance

With APOLLO™, asset and finance leaders can understand how treatment performance connects to lifecycle costs, deferred maintenance, and capital allocation. The result? Smarter investments and defensible funding strategies.

Compliance Officers & Environmental Managers

APOLLO™ provides early warnings on permit limit trends, tracks nutrient removal effectiveness, and generates defensible reports. It gives compliance officers peace of mind and enables a proactive, not reactive, approach to environmental stewardship.

Industry Insights

Learn from industry leaders.

21st Century Water

Meet water leaders facing existing and emerging challenges, and dive deep into novel solutions that produce tangible results in our industry-leading podcast.

The Regional Water Architect: A New Vision for Utility Leadership